The Ultimate Guide to Elevating Your Beverage Brand

Why Partnering with a Co-Packing and Canning Company is a Game-Changer

The canned beverage industry is thriving, with consumers looking for innovative, high-quality portable drinks. For creators of these sought-after beverages, the primary focus is refining their unique formulas. However, the intricacies of production, packaging, and placing these products into the hands of eager consumers can be formidable. This is where the strategic advantage of collaborating with a co-packing and canning company becomes clear. Let's delve into the compelling reasons why such a partnership is not merely a convenience but a strategic move to propel your beverage brand to unparalleled success.

Expertise and Quality Assurance

Co-packing companies offer a treasure trove of specialized knowledge, ensuring every batch of your beverage not only meets but surpasses the highest quality standards. With their expertise in managing various beverage types and intricate packaging needs, your product is in skilled hands. This collaboration ensures your beverages maintain consistent quality, enhancing customer trust and loyalty.

Cost-Effective Solutions

Working with a co-packer can result in significant savings on various fronts. Overhead costs, including equipment maintenance, labor, and storage, can accumulate, cutting your margins. By outsourcing these aspects, you can redirect funds toward crucial areas like marketing and brand development, essential for standing out in a competitive marketplace.

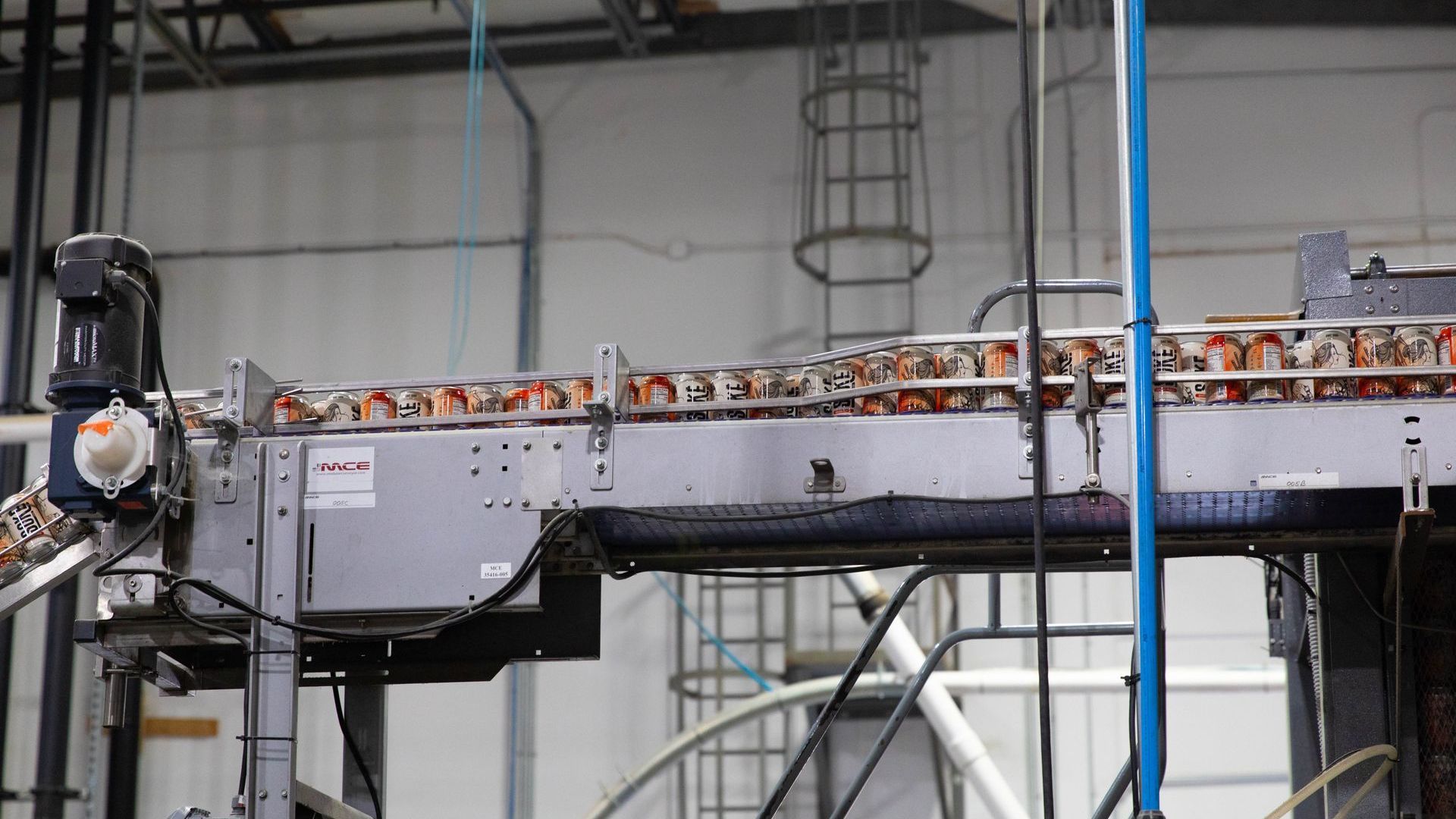

Access to Advanced Technology

Co-packers invest in state-of-the-art canning and packaging technologies, providing services that might be unattainable for small to mid-sized beverage producers. These technologies improve your beverages' shelf life and quality and ensure your products catch the consumer's eye on the shelves.

Scalability and Flexibility

A key benefit of partnering with a co-packer is the ability to adjust production volumes based on market demand. Whether facing a seasonal peak or launching a limited edition, co-packers offer the flexibility to scale production up or down, ensuring you meet demand without the headache of managing logistics.

Speed to Market

In the fast-paced beverage market, speed to market is crucial. Co-packers expedite the process from production to distribution, helping your brand reach consumers quickly. This rapid turnaround is vital for capitalizing on trends and meeting consumer demand on time, keeping your brand ahead of the curve.

Regulatory Compliance and Risk Management

The beverage sector is governed by a complex set of regulations. Co-packers navigate this regulatory maze, ensuring compliance with all laws and minimizing your brand's risk exposure. Their expertise allows you to focus on product development and brand growth.

Focus on Core Competencies

Outsourcing production and packaging enables your team to concentrate on their strengths: developing exceptional beverages and building a community of dedicated fans. This focus is crucial for nurturing your brand's identity and establishing a distinctive position in the market.

Environmental Benefits

Many co-packers are at the forefront of sustainable practices, using eco-friendly packaging and minimizing waste. Partnering with such companies not only aids the environment but also aligns your brand with consumer expectations for corporate responsibility.

Conclusion

Collaborating with a co-packing and canning company is a significant decision for your beverage brand. It represents a partnership that broadens your capabilities, enhances product quality, and improves market agility. Recognizing these advantages enables you to make an informed decision, ensuring your beverages are efficiently delivered to consumers. It's a strategic choice that lays the groundwork for sustained success and growth in the dynamic beverage industry.

Are you ready to transform your beverage concept into a market hit?

Contact RTD Co-Pack in San Diego today. Explore how our tailored co-packing and canning services can elevate your business to the industry forefront. Let’s work together to bring your vision to life, guaranteeing your products meet and exceed market expectations. Join us in San Diego, where innovation meets excellence, and together, RTD will brew success for your brand, one ready-to-drink can at a time.